Cohort 2

Lucy Dougill

University: Bristol

Supervisor: Prof Anthony Croxford & Prof Paul Wilcox

PhD Project: Visual Vibrometry and its Application to NDT Through the Use of Various Video and Signal Processing Techniques

The aim of my project is to explore how large area visual monitoring approaches may be employed to monitor the state of structures through combining the use of ultrasonic guided waves and visual systems. The combination of the visual systems ability to monitor large areas and ultrasonic guided waves ability to penetrate parts at depth that provide additional useful information regarding the structural health of a specimen.

One key focus is to investigate how the sensitivity of the visual methods and their sampling capabilities may be pushed to their limit in order to measure small displacements arising from useful ultrasonic frequencies.

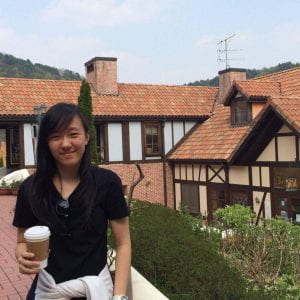

Melody Png

University: Imperial College London

Supervisor: Dr Bo Lan

EngD Project: Material Characterization Using Ultrasonic Testing

The aim of this project is to explore novel developments in the area of ultrasound to characterize critical microstructures of engineering materials, with a particular focus on diffuse ultrasound. The project comprises of: 1. Developing theoretical and computational models to understand the behaviour of diffuse ultrasound to microstructures 2. Conducting experimental validations as well as defining potential applications of this technique. Specifically, this project focuses on Ti-64 alloys in development of a generic solution that could also be applicable to other materials.

Adam Gilmour

University: Strathclyde

Supervisor: Dr Gordon Dobie

Sponsor: BAE Systems Submarines

EngD Project: Robotic Inspection of Complex Welds

Current semi-automated NDT practices often require a great deal of human interaction or interference. This project aims to develop robotic solutions for industrial applications by reducing the amount of hands-on inspection time and through improving the capabilities of automated procedures. We also aim to develop more intelligent inspection systems by incorporating in-situ NDE data into the decision making of any robotic application.

Matt Chandler

University: Bristol

Supervisor: Professor Anthony Croxford

PhD Project: Ultrasonic Inspection for Complex Geometry

Current ultrasonic inspection methods typically rely on line-of-sight access to the region being inspected within a material. In general, this means that geometrically complex components are challenging to inspect in-situ. This project aims to explore how regions of material without line-of-sight access can be inspected by exploiting the reflections of ultrasonic waves from the component geometry, starting with simple geometries before moving on to complex cases. This would enable a wider range of components to be inspected in service, reducing downtime.

Qin Feng

University: Bristol

Supervisor: Professor Bruce Drinkwater

Sponsor: China Scholarship Council

PhD Project: Novel Ultrasonic Coupling Materials

In ultrasonic non-destructive testing (NDT) the use of a coupling liquid or solid between an emitter and the test structure is universal. These layers allow the energy to be transmitted into the structure as well as allowing reflected energy to be received. This project aims to build on recent advances in materials and 3D printing to develop novel coupling layers.

Luke Smith

University: Warwick

Supervisor: Professor Steve Dixon

PhD Project: Ultrasonic Flow Measurement

Thin-walled pipes are widely used for carrying fluids in domestic and industrial environments, but clamp-on ultrasonic flow measurement is difficult because the pipes host guided waves. The aim of this project is to understand the behaviour of leaky guided waves in the pipe-fluid system to enable reliable flow measurement. The received signals are complex, so the first task is to identify the paths by which the ultrasound can reach the detector through experiments and computing. Then, a meter can be developed which utilises this knowledge to make a transit time flow measurement.

Joshua Aigbotsua

University: Bristol

Supervisor: Professor Bruce Drinkwater & Professor Mahdi Azarpeyvand

Sponsor: Baugh and Weedon

EngD Project: Low-Frequency Vibration Inspection of Sandwich Composites

One-sided in-service inspection of certain composite structures (honeycomb-, balsa- and foam-core sandwich) can be successful using a low-frequency vibration method but defect detection is limited, and classification of defects is not currently supported. This project aims to establish a new low frequency inspection method, termed ‘Thickness Resonance’, which has the ability to resolve far-side defects in certain sandwich composite structures. Defects classification, including determining their depth, location and size will be achieved based on comparison with modelled low-frequency responses of a range of structures with different defect types.

Meirbek Mussatayev

University: Bristol

Supervisor: Dr Robert Hughes & Professor Paul Wilcox

PhD Project: In-Line Eddy-Current Characterisation of Carbon Fibre Composites

This project will explore how the material and environmental properties influence the detectability of flaws and structural properties.

The aim and objectives of this project are:

- Determine how layup structure alters the effective conductivity of the structure.

- Characterise differences in ECT response to cured and uncured carbon fibre composite materials.

- Develop advanced measurement & data-analysis techniques for evaluating structural properties such as fibre orientation, stacking sequence and fibre density variations.

Specifically, this project focuses on evaluating of the influence of inspection environment as well as the improving the probe design. Specific requirements for the probe design:

- have a high sensitivity to detect small defects with a very good signal-to-noise ratio when handled with conventional ECT equipment.

- be capable of detecting distinct kinds of defects (morphology and locations).

- be easily customizable and affordable.

Weixin Wang

University: Bristol

Supervisor: Dr Jie Zhang and Professor Paul Wilcox

Sponsor: China Scholarship Council

PhD Project: Metallic Material Grain Structure Characterisation Using Ultrasonic Arrays

A major barrier to characterise materials at the defect early development stage is the lack of techniques to measure material grain structure, mainly including grain size and its texture. This limits the further understanding of the ultrasonic wave interactions between material grains and defects and their ultrasonic signal and image performance. The aim of this project is to develop ultrasonic array techniques to enable the material grain structure to be measured before defect detection. The key is how to use ultrasonic phased arrays to capture data, control wave beamforming and postprocess the data to extract useful information such as material gain size and its texture.

Connor Challinor

University: Imperial

Supervisor: Prof Fred Cegla

Sponsor: NDT Global

EngD Project: Coded Excitation of Ultrasound for Improved Signal Acquisition in Pipeline Inspection Robots

David Robertson-Harra

University: Strathclyde

Supervisor: Dr Katy Tant

PhD Project: Ultrasonic Characterisation of Micro-Texture Regions in Titanium Alloys

Ewan Nicolson

University: Strathclyde

Supervisor: Dr Charles MacLeod

PhD Project: Advanced NDE in Future Oil and Gas Inspection

Chris Stone

University: Bristol

Supervisors: Prof Anthony Croxford and Prof Bruce Drinkwater

Sponsor: Dyson

PhD Project: Acoustic Streaming – Developing a Fundamental Understanding of Acoustic Streaming and its Use for Flow Manipulation and Control

Marco Hernandez Arroyo

University: Bristol

Supervisors: Dr Rob Hughes and Prof Tony Mulholland

PhD Project: Inductive Sensors for Complex Geometries

Evripides Georgiades

University: Imperial

Supervisors: Prof Mike Lowe and Prof Richard Craster

PhD Project: Solutions to Leaky Guided Waves