University of Strathclyde

Supervisor: Dr Gordon Dobie

Industrial Partner: BAE Systems Marine

BAE Systems Marine is a subsidiary of BAE Systems, a British multinational aerospace and defence company. BAE Systems is currently constructing submarines, surface ships and other marine assets for the Royal Navy. In this era of increasing global tensions, BAE Systems submarines play a critical role in ensuring national security and maintaining peace across the world’s oceans.

The manufacture of naval assets involves the inspection of a large volume of components with dissimilar geometries, meaning processes need to be flexible and adaptable for every case. Access restrictions and stringent quality requirements add to the challenge of cost and time effective inspection that does not interfere with other build activities. The preparation and acquisition stages of inspection are therefore time consuming for a human, and prohibitively complex for currently available robotic solutions.

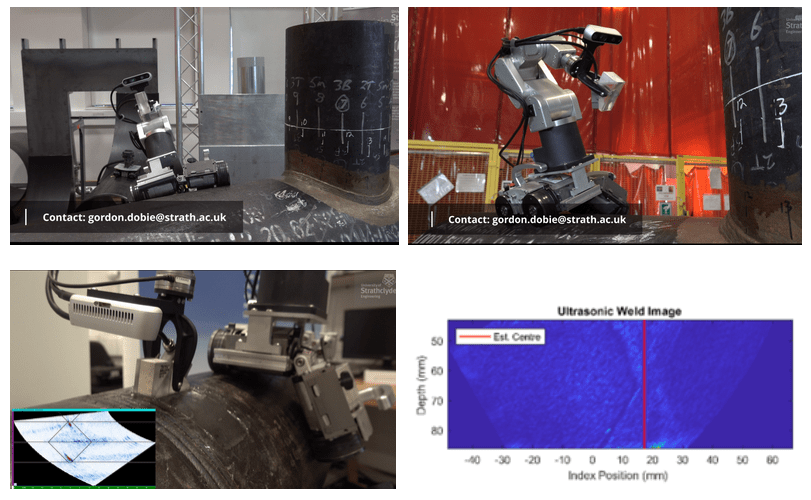

Researchers at Strathclyde have been developing an advanced automated inspection system that is well suited to inspecting complex geometry such as those found in saddle welds. An ongoing research project is developing a demonstrator system to fully automate weld tracking and route planning. However, various technical challenges need to be addressed to expand the scope and applicability of automated robotic systems to become truly general purpose.

This project aims to identify novel methods to address the research questions that currently restrict the accuracy, speed and reliability of automated systems, and to move the system towards being generalised for a wider variety of applications and conditions. The project will focus on control algorithms, addition of new sensors, and hardware design based on the limitations of the current system.

Figure 1: TL: Robot driving over complex geometry. TR: Robot 3D scanning a complex weld. BL: PAUT inspection. BR: Localisation using PAUT signals