University of Strathclyde

Supervisor: Dr Gordon Dobie

Industry Partner: BAE Systems Marine

BAE Systems Marine is a subsidiary of BAE Systems, a British multinational aerospace and defence company. BAE Systems is currently constructing submarines, surface ships and other marine assets for the Royal Navy. In this era of increasing global tensions, BAE Systems submarines play a critical role in ensuring national security and maintaining peace across the world’s oceans.

The manufacture, commissioning and maintenance of naval assets involves the inspection of areas which are inaccessible after assembly has been completed. The internals of pipes, tanks, etc. must be inspected to ensure conformity, cleanliness, and absence of degradation. Commercially available equipment does not offer the control precision, ease of use, data quality and repeatability, or quantitative measurement that is desired. There is an additional requirement for the inspection package to also be capable of retrieving small debris, while maintaining a small overall package.

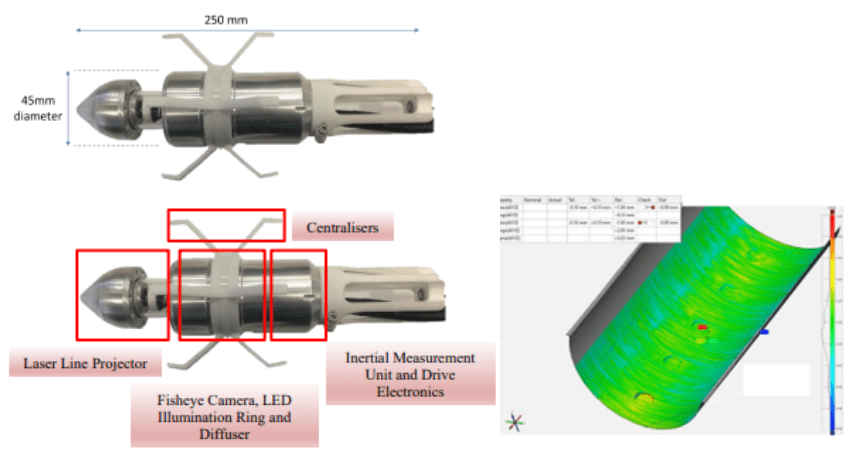

Researchers at Strathclyde have been developing an inspection system that is well suited to generating accurate geometric measurement of pipe internals, using laser scanning; combined with visual data, stitched into a useful 3D image, improving ease of interpretation over conventional video data. Although useful for naval applications, various technical challenges need to be addressed to ensure its widespread application, and use in geometries that have further access restrictions, such as bore size changes. Additionally, the inclusion of a debris retrieval capability would be beneficial.

The project aims to identify novel methods to address the research questions that currently restrict the applicability of remote visual inspection systems to challenging marine applications. The project will focus on design of hardware for deploying sensors in difficult-to-access areas, control algorithms for ease of use, investigation of novel sensor modalities (hyperspectral imaging etc.), and software approaches for improving data processing and presentation.

Figure 1: (Left) Strathclyde probe design, (Right) Data output